Directly relates to space, satellites, and celestial mechanics.

Implies movement, change, and complex systems, fitting for simulations and adaptable designs.

Positions the company as providing answers and practical applications for complex challenges.

- Our company's core business is the specialized design,

fabrication, and extensive testing of advanced robotic satellites for interplanetary exploration, leveraging unique

propellant-less propulsion technology.

- Our product is a highly capable robotic satellite, designed to investigate other planets, moons, and asteroids

across the solar system.

- Our key capability lies in our deep expertise across satellite technologies, from initial concept to rigorous

pre-launch validation. Our technical capabilities, staffing, and equipment for this project are detailed in the

company information section.

Alice Johnson

The ultimate visionary and decision-maker. She is responsible for the overall strategic direction of the company, managing key partnerships and ensuring the company's business goals are met.

Ben Carter

Him and his team are responsible for managing all financial operations, including budgeting, accounting, financial reporting and providing strategic financial insights.

Jeff Hubble

Him and his team oversee the high-level technical integrity, system architecture, and integration for the core technological design and research. Given the company's size, the technical manager is also the Chief Technical Officer (CTO) or Head of Systems Engineering.

Claire Davis

Her and her team are responsible for all software like creating and running the computational models and simulations for missions. Her team also develops the satellite's onboard software and the ground-based control systems.

Gabriel Hayes

Him and his team are responsible for the mechanical, electrical, and propulsion engineering aspects of the satellite's physical build, the design, manufacturing, prototyping, and rigorous testing of the satellite's hardware, housing, and all integrated components. His is the largest team, reflecting the hardware-intensive nature of satellite development.

Chloe Stone

Her and her team are specialists in communication with the satellite. Their role involves acquiring signals, monitoring the continuous data streams, and managing the ground-based communication network.

Visible Spectrum Camera

This module captures high-resolution imagery in the visible light range. While it can be adapted for specialized applications like attaching to Dobsonian-type optical systems for astronomical observation, its primary role on a satellite is often for Earth observation, planetary imaging, or star tracking.

Infrared (IR) Camera

Designed for thermal imaging and heat sensing, this camera detects infrared radiation emitted by objects. It's crucial for applications like environmental monitoring, detecting heat signatures, and analyzing atmospheric conditions where temperature variations are key.

Ultraviolet (UV) Camera

This module specializes in detecting high-frequency ultraviolet light. It's vital for studying phenomena such as planetary atmospheres, aurorae, and stellar activity, where UV emissions provide unique insights.

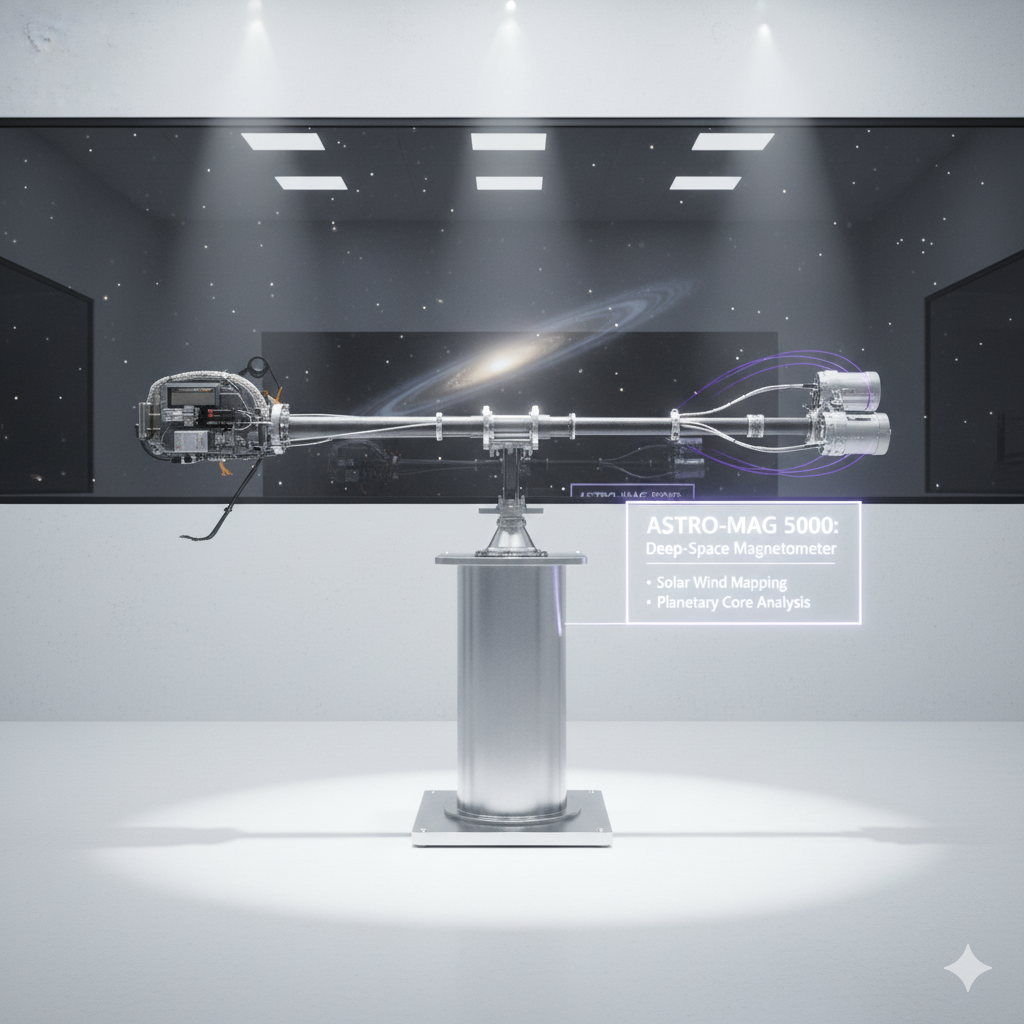

Magnetometer

A precision instrument engineered to measure and record the strength and direction of magnetic fields around planets, celestial bodies, and in space. It's fundamental for understanding magnetospheres, planetary cores, and solar wind interactions.

Metal Detector

This short-range induction sensor is designed to detect the presence of metallic elements. With an effective range of less than one meter, it's ideally suited for close-proximity surveys, such as directly engaging with asteroid surfaces to assess metallic composition.

Gravimeter

This module precisely measures the strength of gravitational fields of planets and other celestial objects. It's crucial for mapping gravitational anomalies, understanding planetary interior structures, and calculating orbital dynamics.

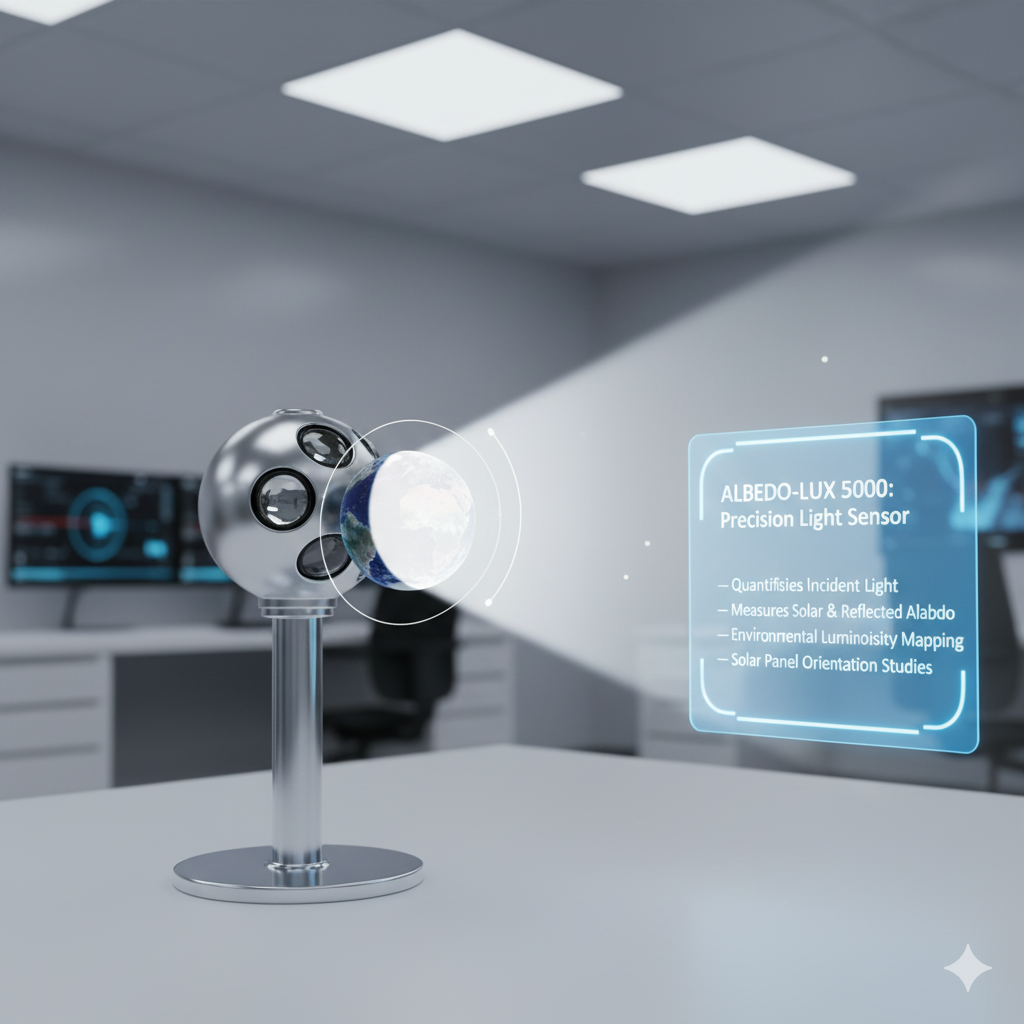

Light Intensity Sensor

This sensor quantifies the intensity of incident light, whether from the sun or reflected from celestial bodies. It's used to determine properties like albedo (reflectivity) and to understand the light environment within the satellite's operational vicinity.

Radio Spectrum Receiver

A specialized receiver that detects and records radio emissions from target objects. It's particularly valuable for studying planetary atmospheres, which generate distinct radio frequency noises through their interaction with solar particles, providing unique acoustic signatures for each planet.

Propulsion System

This innovative, propellant-less propulsion unit generates unidirectional thrust through the interaction of orthogonal electric fields. It operates continuously as long as it has an electrical power source. While it lacks the thrust for planetary surface launch, it provides sufficient self-generated thrust to escape Earth's gravity from Low Earth Orbit (LEO) and execute deep-space missions.

Enclosure/Housing

The robust structural shell of the spacecraft, designed to house and rigidly secure all internal components, protecting them from the harsh space environment and maintaining structural integrity.

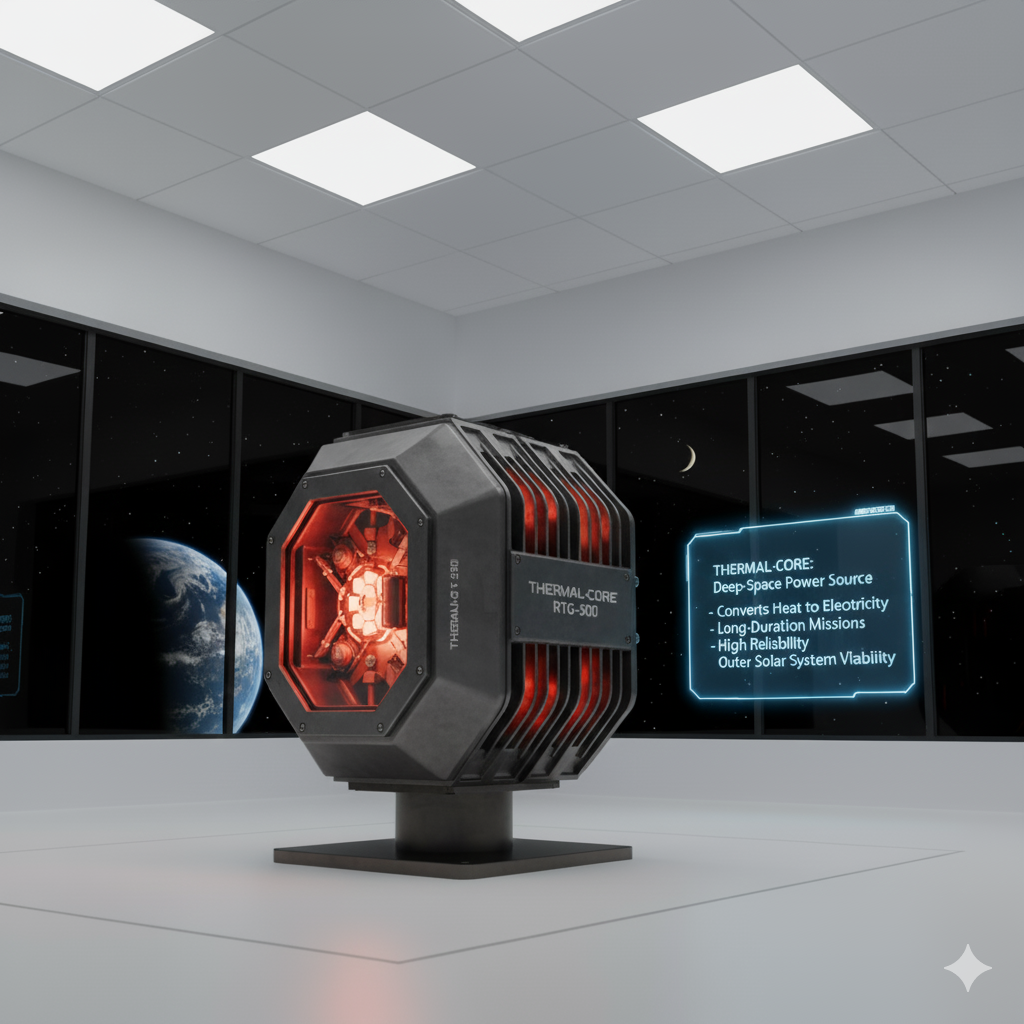

Radioisotope Thermoelectric Generator (RTG)

A highly reliable electrical power source that converts heat from radioactive decay directly into electricity. It's ideal for long-duration missions, especially in the outer solar system where solar power is not viable.

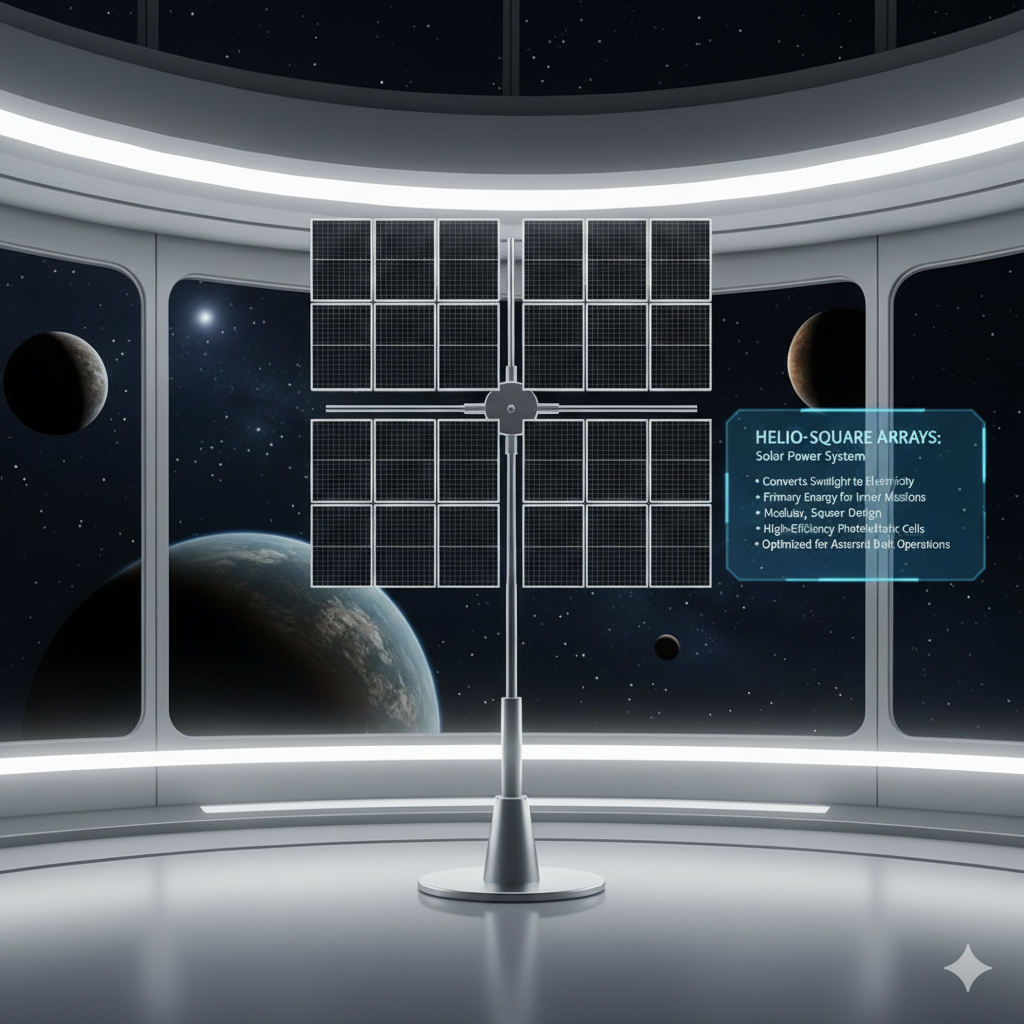

Solar Panel Arrays

These arrays convert sunlight into electrical power, providing the primary energy source for missions within the inner solar system. Their viability extends to the Asteroid Belt, though very large arrays are required at such distances to generate sufficient power.

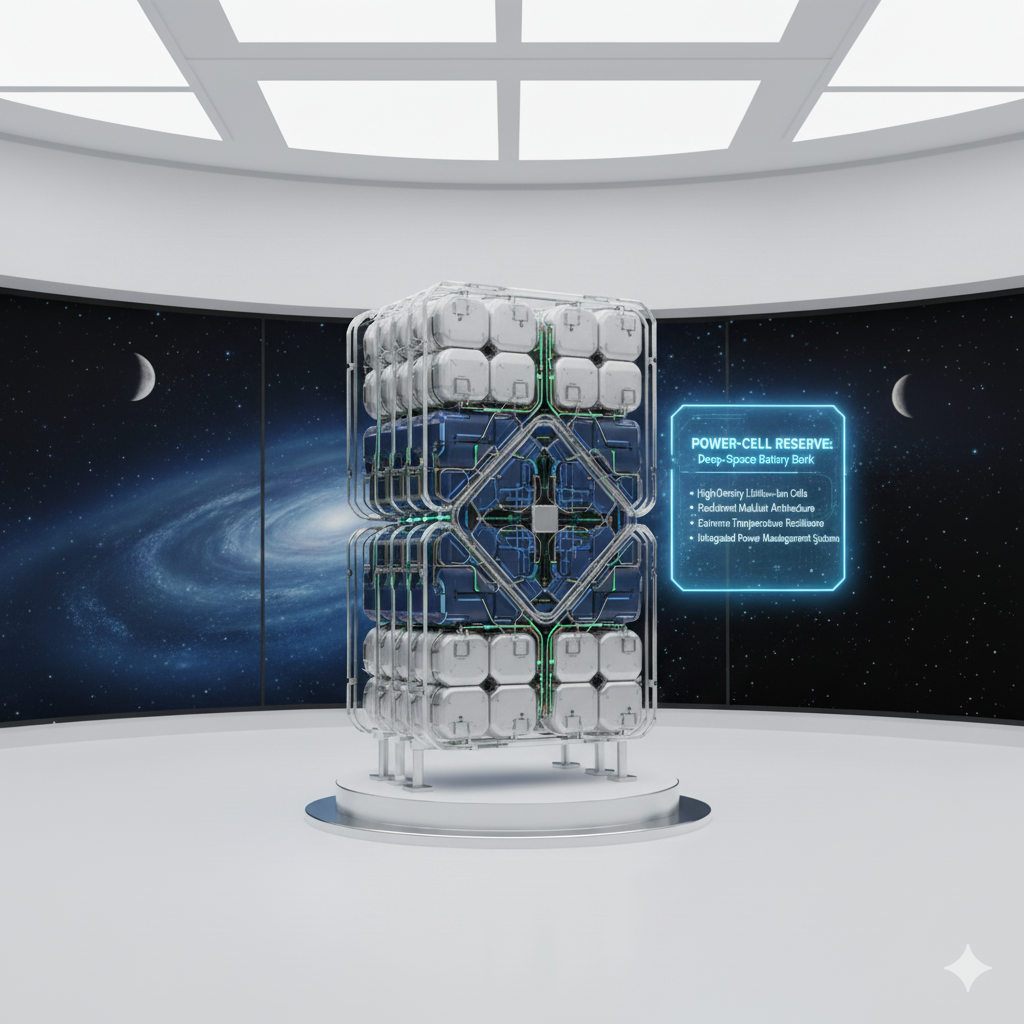

Battery Bank

A critical energy storage unit designed to store electrical charge generated by the RTG or Solar Panel Arrays. These stored reserves provide power for peak operational demands and during periods when primary power generation is limited (for example, in shadows or when solar panels are not optimally oriented).

The company prides itself on our design and engineering capabilities, backed by a team of

seasoned engineers who bring expertise in every area crucial to satellite development that

includes aerospace, mechanical, electrical, software, and systems engineering. Our

engineers excel at designing highly optimized, robust, and reliable satellite platforms tailored

to the specific mission requirements.

Our rapid prototyping capabilities enable us to quickly build and test models/modules of

the components and sub-components of the satellite to see how they fit and interact with the

system. This is an iterative process, with each prototype we can build upon the success of

previous models as well as improve/resolve the issues that pertained to previous iterations.

Strict tolerances in our manufacturing process leads to high quality control assurances via

our state-of-the-art manufacturing facilities, equipped with precision machinery and staffed

by highly skilled technicians. It ensures every component we manufacture meets the

rigorous demands of the space environment.

We utilise advanced modeling and simulation software designed in-house. Before we

create a physical component, we first model it in the computer to see if it fits within the

system. Not only can we see how it fits, but also simulate the component working within the

system of the satellite and then simulate how the satellite would operate within the

environment of space. Doing it right the first time, or in fewer attempts, saves us valuable

time and money by avoiding the need to physically recreate components over and over.

We deploy rigorous testing and validation for our satellites to meet industry standards. We

subject our satellites to extreme environmental conditions - vacuum, vibration, thermal

cycling, radiation testing and more, to mimic the harsh realities of space to ensure absolute

reliability and mission success.

On-going research and development(R&D) is done to find and explore new materials and

manufacturing processes to incorporate into the project. We are constantly investigating

lighter materials that yield more strength, also known as researching high strength-to-weight

materials. Deploying techniques such as additive manufacturing such as 3D printing and/or

subtractive manufacturing such as CNC.

We are also working on and fine-tuning the propulsion systems to make them more

efficient while also maintaining great maneuverability.

Developing new antenna designs, frequency bands, and data processing to handle

more bandwidth in the transmission back to Earth for higher speed and stability of payload

telemetry data.